Exploring the Heart of an Infrared Camera: Uncovering the Technology Behind Thermal Imaging

In the field of imaging technology, infrared cameras play a vital role in capturing images that cannot be perceived by the human eye. These cameras are used in a variety of applications, from industrial inspection to medical diagnosis. At the heart of a thermal imaging camera is the thermal imaging camera core, an essential component that enables the camera to detect and record infrared radiation. In this article, we'll explore the concepts at the heart of infrared cameras and take a deep dive into the different types available on the market.

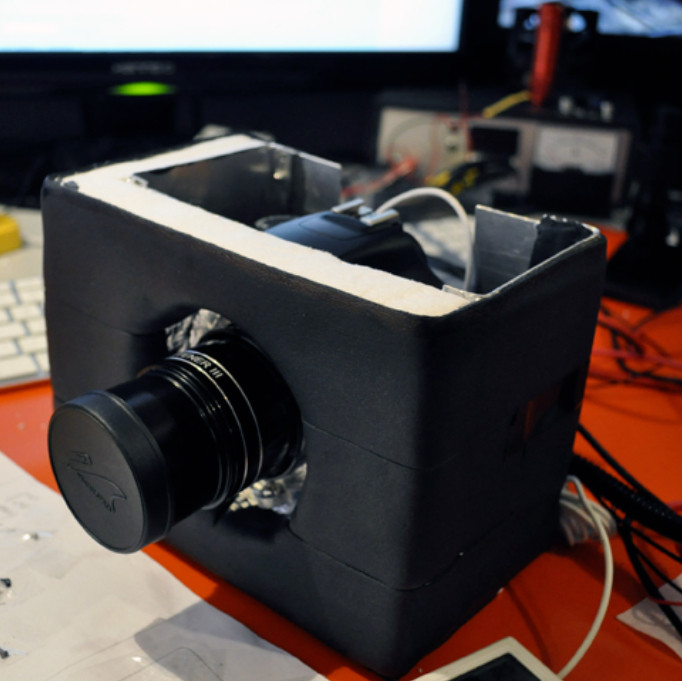

Understanding the Infrared Camera Core

The core of an infrared camera consists of several key components, including infrared detectors, optics, signal processing circuits, and output interfaces. Infrared detectors, typically made of materials such as indium antimonide (InSb) or vanadium oxide (VOx), sense infrared radiation emitted or reflected by objects in the environment. An optical module captures this radiation and focuses it onto a detector, enabling it to generate an electrical signal proportional to the intensity of the infrared radiation.

The Core Working Principle of Infrared Camera

At its core, thermal imaging cameras work on the basis of detecting temperature differences between objects. Every object with a temperature above absolute zero (-273.15℃) emits infrared radiation. The core detectors capture this radiation and convert it into an electrical signal. The signal is then processed and converted into a visible image using algorithms and calibration techniques. This image is often represented in various color palettes, enabling users to interpret temperature changes and detect anomalies.

Types of Infrared Camera Cores

There are different types of thermal imaging camera cores, each designed for specific applications and performance requirements. The three main types of thermal imaging camera cores are uncooled, cooled, and megapixel cores. Let's explore each type in detail.

Uncooled Infrared Camera Core

Uncooled thermal imaging cores are widely used due to their small size, low cost, and low power consumption. These cores employ microbolometer technology, in which infrared detectors are sensitive to temperature changes. Microbolometer arrays consist of tiny resistive elements that detect temperature changes and convert them into electrical signals. Uncooled cores have good sensitivity and can operate at room temperature without complex cooling mechanisms.

Cooling the IR Camera Core

Cooled infrared camera cores, also known as cryogenically cooled cores, employ a more advanced technology called quantum detectors. These cores need to be cooled to cryogenic temperatures, usually achieved using Stirling coolers or liquid nitrogen, to increase detector sensitivity and reduce noise. The cooled core is known for its superior performance, high sensitivity, and excellent image quality, making it suitable for demanding applications such as remote monitoring and scientific research.

Megapixel Infrared Camera Core

The megapixel infrared camera core represents a major leap forward in infrared imaging technology, delivering high-resolution images with greater detail and clarity. These cores integrate advanced focal plane array (FPA) sensors with multi-million pixels that can capture complex thermal patterns and subtle temperature changes. Megapixel cores find applications in research, aerial inspection, and surveillance, where accurate thermal analysis is critical.

Resolution and Sensitivity

Resolution and sensitivity are two fundamental factors to consider when evaluating the core performance of an infrared camera. Resolution refers to the number of pixels in the captured image, the higher the resolution, the more detailed the thermal information. Sensitivity, on the other hand, represents the core's ability to accurately detect small temperature differences. The highly sensitive core captures small changes in thermal radiation, enabling the identification of small temperature gradients.

Application of Infrared Camera Movement

Infrared camera chips can capture thermal data that is invisible to the human eye, so they have a wide range of applications in various industries. Let's explore some key application areas:

Industrial and Manufacturing Applications

Thermal imaging cameras are widely used in industry and manufacturing for quality control, preventive maintenance, and process optimization. These cores can detect thermal anomalies, identify equipment failures, monitor temperature changes, and help in the early detection of potential failures. Industrial plants utilize infrared camera cores to improve operational efficiency, reduce downtime and enhance overall safety.

Security and Surveillance Applications

Infrared camera cores play a vital role in security and surveillance systems, especially in low-light or nighttime environments. These cores detect heat signatures and provide a clear thermal image, enabling effective monitoring and identification of intruders or potential threats. Infrared camera cores are widely used in perimeter security, border control, and critical infrastructure protection.

Medical Application

In the medical field, infrared camera chips are used in various diagnostic applications. They capture thermal images of the human body, enabling non-invasive temperature monitoring and identification of abnormal thermal patterns. Infrared camera cores find applications in areas such as thermal imaging, fever screening, vascular imaging, and wound assessment.

Building and Energy Applications

Thermal imaging cameras are valuable tools for building inspections, energy audits, and energy management. They can identify insulation gaps, air leaks, and heat loss in buildings, allowing energy-saving measures to be implemented and overall thermal efficiency to be improved. In the field of renewable energy, thermal imaging camera cores help inspect solar panels and identify faulty cells or areas of reduced efficiency.

In Conclusion

The infrared camera core is the backbone of infrared imaging technology, capable of capturing and interpreting thermal radiation. Different types of cores are available, including uncooled, cooled, and megapixel cores, so you can choose the most suitable option based on your specific needs and application requirements. The versatility and growing popularity of thermal imaging camera cores in various industries mean that they can play an invaluable role in improving efficiency, safety, and diagnostics. If you want to buy an infrared camera core, welcome to contact us.

Javol is a professional custom infrared thermal imaging equipment manufacturer. Relying on advanced compound semiconductor materials, multi-spectral, high-sensitivity photoelectric sensor chips, with deep learning AI algorithm as the engine, it integrates miniature human night vision technology, infrared thermal imaging technology, short-wave Infrared technology, fusion technology designed, developed, and manufactured by Multispectrum, advanced imaging products and system solutions are widely used in application fields such as machine vision, autonomous driving, drone payloads, high-end manufacturing and medical diagnosis.