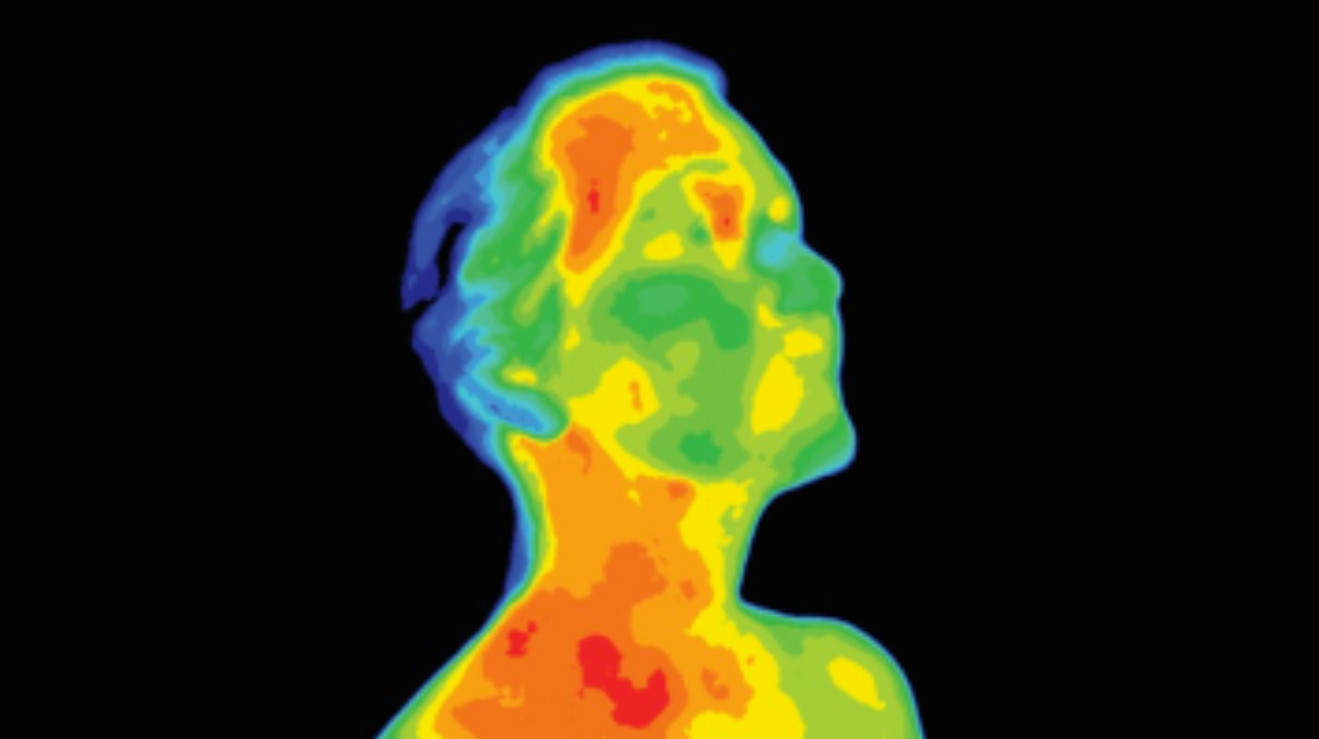

How Does Thermal Imaging Affect the Way Temperature Is Measured?

Thermal imaging cameras have impacted the way temperature is measured across industries. These cameras have features and features that enable non-contact measurements, accuracy, thermal pattern views, and the ability to indicate problems.

The greatest advantage of thermal imaging cameras is their ability to be non-contact with the object, surface, or industrial process whose temperature is being monitored. This allows the camera to be used in hazardous areas and hard-to-reach areas.

Equipped with the latest algorithms, features, and high-resolution sensors, the cameras are able to provide accurate temperature readings in industrial processes. Additionally, real-time visualization of thermal patterns and temperature gradients can help identify problems in industrial processes and enable predictive maintenance before downtime or product damage occurs. Addressing these issues early can reduce costs and downtime.

Thermal imaging cameras provide more than just images, most models allow for data collection. The advanced software comes with many models and this feature allows users to generate and generate in-depth reports, trends, and analyses related to their industrial processes.

Where Do We Use Thermal Imaging Cameras?

Thermal imaging cameras have migrated to other fields and found many uses.

Thermography for electrical maintenance is very versatile. For example, powerline technicians use thermal imaging to locate and pinpoint joints and components that are at risk of overheating because they already emit more heat than higher-strength sections. They can also help spot loose connections or devices that are starting to fail.

Plumbers use thermal imaging cameras to check for possible leaks, mostly through walls and pipes. Because these devices can be used from a distance, they are ideal for spotting potential problems in equipment that is hard to reach or could pose safety concerns for workers.

Mechanics and building construction technicians who work on insulation use imaging technology to quickly identify leaks, which is important for maintaining efficient temperature regulation within buildings. At a glance, they can analyze a building's structure and spot flaws. Heat loss from walls, HVAC equipment, doors, and windows are common thermal performance issues that is easily spotted by thermal imaging cameras.

Mechanics and building construction technicians who work on insulation use imaging technology to quickly identify leaks, which is important for maintaining efficient temperature regulation within buildings. At a glance, they can analyze a building's structure and spot flaws. Heat loss from walls, HVAC equipment, doors, and windows are common thermal performance issues that is easily spotted by thermal imaging cameras.

Thermal imaging technology brings significant benefits to traffic navigation, especially when driving at night. For example, marine navigation uses it to clearly see other ships, people, and obstacles when out at sea at night. In recent years, cars have begun to be equipped with infrared cameras to alert drivers to people or animals outside the range of street lights or headlights.

There are also practical uses in healthcare and medicine, such as spotting fevers and abnormal temperatures. This has proven to be especially important at airports, as these thermal cameras can quickly and accurately scan the temperature of all incoming and outgoing passengers, critical during recent outbreaks of diseases such as SARS and Ebola. In addition, thermal imaging cameras have been shown to aid in the diagnosis of a range of conditions related to the neck, back, and extremities, as well as circulatory problems.

Firefighters use thermal imaging to help them see through smoke, especially during rescue missions when they are looking for people in obscure and dangerous environments. They also use thermal imaging cameras to quickly identify live fires so they can intervene before they spread.

Police and law enforcement agencies incorporate thermal imaging cameras into their surveillance equipment to locate suspects, especially at night, and to investigate crime scenes and search and rescue operations. They are superior to night vision devices because they do not require any ambient light and are not affected by glare, which is critical for tactical missions.

Science and research are certainly areas that would benefit greatly from the use of thermal imagers to accurately and precisely visualize thermal patterns, such as the dark side of the moon.

Other applications using thermal imaging cameras include heating, ventilation, and air conditioning installations, mold inspection, quality assurance during glass manufacturing, etc.

You don't necessarily expect thermal imaging equipment to save money, but it makes sense when you consider all of its features. After subtracting the upfront cost of buying the equipment, they can undoubtedly save your business or home thousands of dollars or more in potential maintenance and repair costs that could have been incurred if a fault, leak, or weakness wasn't caught early on.

However, it's important to realize that while thermal imaging has all of these applications, it's often best to use additional instruments or tools when appropriate to confirm what you're seeing. Also, it's worth noting that thermal imaging cameras can't see through walls and objects, but only pick up what's reflected off them.

Selecting and Purchasing a High-Quality Thermal Imaging Camera

Using high-quality products is essential to ensure accurate measurements are detected and recorded. A big difference between the different types of thermal imaging cameras is the resolution and clarity of the images they provide.

Thermal imaging is an impressive and compact way to identify, measure, and visualize thermal patterns, especially in environments that lack visible light. Equipped with efficient, high-quality thermal imaging cameras for a wide range of applications, from industry to health to research and science and more. If you want to buy a thermal imager, please contact us.

Javol is a custom infrared thermal imaging equipment manufacturer for professionals. Relying on advanced compound semiconductor materials, multi-spectral, high-sensitivity photoelectric sensor chips, with deep learning AI algorithm as the engine, integrated miniature human body night vision technology, infrared thermal imaging technology, short-wave infrared technology, fusion technology and design, the advanced research and development and manufacturing of Multispectrum Imaging products and system solutions are widely used in applications such as machine vision, autonomous driving, drone payloads, high-end manufacturing, and medical diagnosis.